Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

Dielectric fittings are necessary in plumbing to prevent corrosion. They separate different metals to avoid electrical reactions.

Understanding when to use dielectric fittings is essential for maintaining a healthy plumbing system. These fittings act as barriers, preventing metal pipes from corroding when they connect. Corrosion can cause leaks and damage over time, leading to costly repairs. Knowing the right situations to use dielectric fittings can save you time and money.

This blog will guide you on the importance of these fittings and when they are most needed. Stay with us to ensure your plumbing system remains efficient and long-lasting.

Credit: www.tylok.com

Introduction To Dielectric Fittings

Dielectric fittings prevent corrosion between different metal pipes in plumbing systems. These fittings are essential when connecting copper pipes to steel pipes. They act as a barrier, stopping electric currents and protecting the plumbing from damage.

When you think about the plumbing in your home or office, you might not immediately consider the small, yet vital components like dielectric fittings. These fittings play a crucial role in maintaining the safety and longevity of your piping systems. But what exactly are they, and why are they so important?

###

Purpose And Function

Dielectric fittings are used to prevent corrosion in pipes where two different metals meet. This is essential because when metals like copper and steel come into contact, they can create a reaction that speeds up corrosion. This reaction is called galvanic corrosion and can cause leaks and damage over time.

These fittings act as a barrier, stopping the electrical current that leads to this kind of corrosion. Imagine having a busy road with no traffic lights—chaotic, right? Dielectric fittings are like those traffic lights, providing order and preventing disaster.

###

Common Applications

You often find dielectric fittings in water heater installations. When a copper pipe connects to a steel water heater, a dielectric fitting is necessary to ensure longevity.

They’re also common in HVAC systems, where different metals are used in piping. The fitting helps maintain system integrity and efficiency.

Have you ever checked your home’s water system for these small but mighty components? Ensuring you have dielectric fittings in the right places can save you a lot of trouble down the road.

By understanding the purpose and common applications of dielectric fittings, you gain insight into their vital role. So next time you look at your plumbing, you’ll know exactly what keeps it running smoothly.

Material Compatibility Issues

Material compatibility is crucial in plumbing systems. It prevents damage and ensures safety. Different metals can react negatively when paired. This reaction can cause corrosion and leaks. Dielectric fittings help avoid these issues. They act as barriers between incompatible metals.

Galvanic Corrosion Risks

Galvanic corrosion occurs between dissimilar metals. When two different metals touch, they can corrode. Water acts as a conductor, speeding up this process. The metal with less resistance corrodes faster. This weakens the plumbing system. Dielectric fittings prevent direct metal contact. This reduces the risk of galvanic corrosion.

Metal Pairing Concerns

Some metals should not be paired directly. Copper and steel are a common example. When paired, they can cause corrosion. This leads to leaks and pipe damage. A dielectric fitting separates them. This ensures they do not touch directly. Proper pairing extends the life of plumbing systems.

Signs You Need Dielectric Fittings

Dielectric fittings play a crucial role in preventing corrosion in plumbing systems. But how do you know if you need them? Recognizing the signs early can save you a lot of trouble and expense. Below are the key indicators that you may need dielectric fittings.

Corrosion Indicators

Corrosion can cause serious damage to your plumbing system. Look for discolored water from your taps. This is often a sign of corroded pipes. Rust stains around fixtures are another clear sign. Check for leaks and wet spots on the walls or ceilings. These could indicate hidden corrosion issues. If you see any of these signs, you likely need dielectric fittings.

System Performance Problems

Decreased water pressure is a common sign of system performance issues. This may be due to corrosion causing blockages. Listen for unusual sounds from your pipes. Banging or clanging noises can indicate internal corrosion. If your water heater or other appliances seem less efficient, it could be due to corrosion. These performance problems suggest the need for dielectric fittings to prevent further damage.

Installation Best Practices

Proper installation ensures dielectric fittings perform effectively. Avoid corrosion and maintain safe connections. Following best practices can prevent costly issues and extend lifespan.

Correct Placement Techniques

Place dielectric fittings between different metal pipes. This prevents electrical currents from causing corrosion. Position fittings in accessible locations for easy inspection and maintenance. Ensure they are visible and not hidden behind walls or obstacles.

Tools And Equipment

Use the right tools for installation. A pipe wrench for tightening fittings is essential. A torque wrench ensures correct tightness without damage. Use a pipe cutter for clean cuts. This helps in creating secure connections. Teflon tape or pipe thread sealant prevents leaks. Always wear safety goggles and gloves during installation for protection.

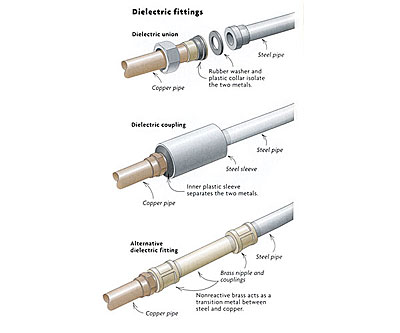

Types Of Dielectric Fittings

Dielectric fittings are essential for preventing electrochemical corrosion between dissimilar metals. They provide insulation that protects pipes and fittings from damage. Understanding the types of dielectric fittings helps in selecting the right one for your needs.

Unions And Flanges

Unions offer easy disconnection of pipes without cutting. They separate pipes made from different metals to reduce corrosion risk. Flanges connect pipes and provide a sealed joint. They allow for easy maintenance and inspection.

Bushings And Inserts

Bushings are used to protect threaded connections. They act as insulators between different metal types. Inserts are placed inside fittings to isolate metals. They prevent direct contact, reducing corrosion.

Credit: www.finehomebuilding.com

Maintenance And Inspection

Dielectric fittings play a crucial role in preventing corrosion between dissimilar metals in plumbing systems. But to ensure they function effectively, regular maintenance and inspection are essential. As you incorporate dielectric fittings into your system, understanding how to keep them in top shape can save you time, money, and headaches. Let’s dive into the practical aspects of routine checks and troubleshooting tips.

Routine Checks

Regular checks can be your first line of defense against potential issues. Set a schedule for inspecting your dielectric fittings, perhaps every six months. During these checks, look for signs of wear and tear or corrosion. Is there any rust forming around the fittings? Catching these early can prevent larger problems down the line.

Consider keeping a record of your inspections. This log can be invaluable, especially if you notice recurring issues. It might reveal patterns or highlight specific areas needing more attention. You might even discover that certain environmental factors are affecting your fittings more than others.

Troubleshooting Tips

Encountering issues with your dielectric fittings can be frustrating. When problems arise, start by examining the fitting and surrounding pipes. Are they properly aligned? Misalignment can lead to stress and eventual failure. Adjust them as needed to ensure a snug fit.

If corrosion is present, it might be time to replace the fitting. However, before taking drastic measures, check for leaks or unusual noises. These could indicate other underlying issues. Tighten any loose connections and see if the problem persists.

Always ask yourself: Is there something in your environment contributing to these issues? Factors like humidity or chemical exposure might be influencing the integrity of your fittings. Understanding these can help in selecting better materials or protective measures next time.

Maintenance isn’t just about fixing problems—it’s about prevention. By taking proactive steps, you can ensure your dielectric fittings last longer and perform better. Have you had any unexpected experiences with your fittings? Share your insights and join the conversation in the comments below.

Cost Implications

Understanding the cost implications of installing dielectric fittings is crucial for homeowners and businesses alike. While these specialized fittings are essential to prevent corrosion and maintain system integrity, their financial impact can vary. It’s not just about the initial expense; long-term savings and budgeting play significant roles in determining their true value. Let’s dive into the details.

Budgeting For Installations

Planning your budget for dielectric fittings involves more than just the purchase cost. Consider the installation fees, which can vary based on your location and the complexity of the job. Ask yourself: Is it more cost-effective to hire a professional, or can you manage a DIY project?

Also, think about the potential for unexpected expenses. If old pipes need replacing, your budget might need adjusting. Being prepared for these surprises can save you from financial strain.

To make a smart choice, compare quotes from different suppliers and installers. A little research can go a long way in finding the best deal without compromising quality.

Long-term Savings

While the upfront costs of dielectric fittings might seem daunting, consider the long-term benefits. These fittings prevent corrosion between dissimilar metals, extending the life of your plumbing systems. This means fewer repairs and replacements over time.

Think about how much you could save on maintenance fees alone. Investing in quality fittings now can lead to significant savings down the line. Wouldn’t you prefer to spend your money elsewhere?

Moreover, efficient plumbing systems can reduce energy costs, especially in heating applications. A well-maintained system keeps your bills low and your stress levels lower.

Incorporating dielectric fittings into your plumbing plan is not just a financial decision; it’s a strategic one. Are you ready to make a choice that saves money and ensures peace of mind?

Credit: mbpindia.com

Industry Standards And Regulations

Dielectric fittings are required to prevent galvanic corrosion between dissimilar metals. These fittings help maintain safety and efficiency in plumbing systems. Ensuring proper installation is crucial for compliance with industry standards and regulations.

When it comes to the installation of dielectric fittings, understanding industry standards and regulations is crucial. These guidelines ensure the safety and efficiency of your plumbing systems. Familiarizing yourself with these standards can prevent costly mistakes and ensure compliance with legal requirements. Let’s dive into the specifics of compliance requirements and safety protocols that govern the use of dielectric fittings.

Compliance Requirements

Industry standards are not just arbitrary rules; they are set to ensure that systems function correctly and safely. For dielectric fittings, these standards dictate materials and installation practices to prevent galvanic corrosion. Imagine installing fittings without considering these requirements; you might face leaks or system failures.

Did you know that using the wrong materials can void warranties? It’s true. Manufacturers often specify the types of fittings that should be used to maintain product guarantees. You wouldn’t want to jeopardize a warranty due to a simple oversight.

Regulatory bodies often update standards. Are you keeping track of these changes? Staying informed ensures your installations are up-to-date and compliant.

Safety Protocols

Safety protocols are designed to protect both the systems and the individuals who work on them. When dielectric fittings are installed incorrectly, it can lead to dangerous situations. Consider the risk of electrical shock due to improper installation.

Have you ever thought about how a small oversight can lead to bigger safety issues? Ensuring proper installation of dielectric fittings is not just about following rules—it’s about protecting lives.

Safety checks should be routine. Are you conducting them regularly? Regular inspections can catch potential problems before they escalate into hazardous situations.

Remember, industry standards and regulations are not just a bureaucratic necessity. They are there to protect you and your systems. Stay informed, follow compliance requirements, and never underestimate the importance of safety protocols.

Frequently Asked Questions

Where Are Dielectric Fittings Required?

Dielectric fittings are required where copper and galvanized steel pipes connect. They prevent corrosion and ensure electrical isolation. Install them in plumbing systems to prolong pipe life and maintain safety. Use dielectric unions in water heaters, boilers, and other systems with mixed metal piping to avoid galvanic corrosion.

When To Use A Dielectric Fitting?

Use a dielectric fitting to prevent galvanic corrosion between dissimilar metal pipes. It insulates and separates copper from steel or iron. Ideal for plumbing applications to ensure longevity and efficiency. Maintain optimal water flow and system integrity by minimizing corrosive interactions.

What Metals Require Dielectric Fittings?

Metals requiring dielectric fittings include copper and steel. These fittings prevent galvanic corrosion when these metals are joined.

What Pipes Need A Dielectric Union?

Pipes made of different metals, such as copper and steel, need a dielectric union. This prevents galvanic corrosion.

Final Words

Dielectric fittings are crucial for preventing corrosion in plumbing systems. They separate dissimilar metals, reducing the risk of galvanic corrosion. This keeps the system efficient and safe. Always use dielectric fittings in environments with mixed metal connections. They ensure longevity and reliability.

Regular maintenance checks can help identify when these fittings are needed. Protect your plumbing investment with the right fittings. Understanding their role aids in making informed decisions. Proper use of dielectric fittings leads to smoother operations and fewer repairs. Ensure your plumbing system’s health with these essential components.