Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

Have you ever experienced an unexpected cold shower because your gas heater suddenly stopped working? Or perhaps your stove just won’t light up when you need it most?

These frustrating scenarios might be pointing to a common culprit—gas valve failure. Understanding what causes gas valve failure can save you from inconvenient interruptions and potential safety hazards in your home. You’re not alone in facing these issues. Many homeowners experience the same problems, often without realizing the underlying cause.

By uncovering the reasons behind gas valve failure, you can take proactive steps to prevent it and ensure your appliances run smoothly. So, if you’re tired of dealing with unreliable gas appliances and want to keep your home safe and functional, keep reading. You’ll discover the key factors that lead to gas valve failure and learn how to safeguard your home from these common setbacks.

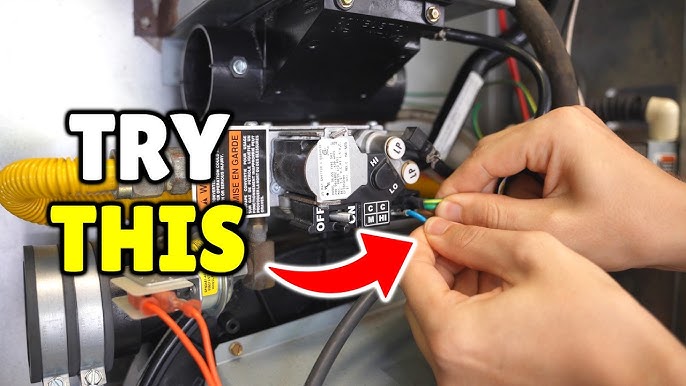

Credit: www.youtube.com

Common Types Of Gas Valves

Gas valves are crucial in controlling the flow of gas in systems. Different types of gas valves exist to suit various applications. Understanding these can help diagnose valve failures. Let’s explore the common types.

Ball Valves

Ball valves use a spherical disc to control flow. They offer quick shutoff with a simple quarter-turn. Their design minimizes leaks and is excellent for high-pressure systems. Failure can occur due to seal wear or corrosion.

Gate Valves

Gate valves operate by lifting a gate out of the path. They’re ideal for full open or closed positions. They are not suitable for regulating flow. Problems arise from debris blockage or improper seating.

Globe Valves

Globe valves regulate flow through a movable disc. They provide precise control and are suitable for throttling. Failures may stem from stem wear or erosion. Regular maintenance can prevent these issues.

Butterfly Valves

Butterfly valves have a rotating disc for flow control. They are compact and cost-effective for large systems. They might fail due to seal damage or disc misalignment. Checking seals can prevent problems.

Signs Of Gas Valve Failure

Gas valve failure can disrupt your home’s safety and efficiency. Recognizing the signs early helps prevent bigger issues. Here, we explore common symptoms of gas valve problems.

Leakage Symptoms

Smelling gas indoors signals a potential leak. This could mean a faulty gas valve. Check for hissing sounds near the valve. These sounds often indicate gas escaping. Also, look for dead plants or grass near outdoor valves. Gas leaks can kill vegetation quickly.

Operational Issues

Gas appliances not working properly can point to valve trouble. If your stove won’t ignite, the valve may be failing. Water heaters that don’t heat might have a valve issue. Sudden changes in appliance performance are strong indicators. Always inspect if appliances act strangely.

Noisy Valves

Rattling or banging sounds from valves are warning signs. These noises suggest internal damage or wear. Listen for unusual sounds when appliances are on. They often mean the valve is struggling. Constant noise should prompt a check-up. Early detection prevents dangerous situations.

Environmental Factors

Extreme weather conditions and temperature fluctuations can damage gas valves. Moisture, dust, and debris also contribute to their deterioration. These environmental factors cause valves to malfunction over time, leading to potential safety hazards.

Gas valve failure can be a frustrating and costly issue, especially when environmental factors come into play. These factors can silently wreak havoc on the functionality of your gas valve, leading to unexpected malfunctions. Understanding how your surroundings impact these vital components can help you take proactive steps to prevent failures.

Temperature Extremes

Extreme temperatures can put a strain on gas valves. If you live in a region with severe winters or scorching summers, your gas valve might be vulnerable. Cold temperatures can cause components to become brittle, while excessive heat can lead to expansion and contraction, compromising seals and joints. Have you ever noticed how your car battery struggles in the cold? Gas valves can face similar challenges. Regular maintenance can help mitigate these effects by ensuring your valve components remain resilient.

Humidity Levels

Humidity is another factor that can lead to gas valve failure. High moisture levels can cause rust and corrosion, which can jam moving parts or degrade seals. You might have noticed how a damp environment can make metal tools rust faster.

Similarly, gas valves can suffer in high humidity conditions. Installing a dehumidifier or ensuring proper ventilation can help control the moisture levels around your gas valves.

Corrosive Environments

Corrosive environments are particularly brutal for gas valves. If your home is near the ocean or a factory with chemical emissions, your valves might be at risk. The salty air or chemical particles can accelerate wear and tear on metal components.

Have you ever seen a bike left outside near the sea? It doesn’t take long for rust to set in. Consider using protective coatings or choosing valves made from corrosion-resistant materials to safeguard against these harsh conditions. Being aware of these environmental factors empowers you to take action.

Regular inspections, proper maintenance, and suitable protective measures can prolong the life of your gas valves. What steps can you take today to protect your home’s vital systems? Addressing these factors not only saves money but also ensures safety in your everyday living space.

Material And Design Flaws

Material and design flaws are common causes of gas valve failure. Such flaws can lead to serious issues, affecting the efficiency and safety of gas systems. Understanding these flaws is crucial for maintaining reliable gas valve operations.

Poor Quality Materials

Gas valves made from poor materials often fail quickly. Inferior metals can corrode easily, leading to leaks. Plastic components may crack under pressure, disrupting flow. This compromises the valve’s performance. High-quality materials resist wear and ensure longevity.

Manufacturers sometimes cut costs by using cheaper materials. This choice can result in unsafe valves. Poor materials decrease the valve’s reliability. Investing in quality materials improves system safety. It also reduces maintenance needs.

Design Inadequacies

Design flaws can lead to gas valve failure. Poor design may cause misalignment in valve parts. This misalignment can result in inefficient operations. Incorrect sizing of components can also cause problems. It leads to improper pressure regulation.

Complex designs might increase failure risks. Simpler designs often perform better. They are easier to maintain and less prone to errors. Proper design ensures smooth and safe gas flow. It also enhances the valve’s overall durability.

Installation Errors

Gas valve failure often stems from incorrect installation errors. Misaligned components can lead to inefficient operation and potential hazards. Ensuring proper installation is critical to avoid these issues.

Gas valve failure can lead to serious issues in your home or business, and a common culprit is installation errors. Whether you’re installing a new valve or replacing an old one, attention to detail is crucial. Mistakes during installation can compromise the safety and efficiency of your gas system. Let’s explore some common installation errors and how they can cause gas valve failure.

Improper Fitting

Improper fitting of a gas valve can cause leaks, reducing the system’s effectiveness and posing a safety risk. One wrong twist or a loose connection can lead to gas escaping. Imagine tightening a screw too much or too little, and you get the picture. I once had a friend who decided to take on a DIY gas valve installation. He skipped the step of checking the fittings thoroughly.

A week later, he noticed a faint smell of gas, a clear sign something was amiss. It turned out that a simple adjustment to the fittings fixed the issue. How often do you double-check connections when installing something? In gas systems, this step is non-negotiable.

Incorrect Valve Type

Using the wrong type of valve for your gas system is another common installation error. Each valve is designed for specific conditions and types of gas. Using the incorrect valve can lead to failure and hazardous situations. Think of it like using a key from one lock on another—it just doesn’t fit right.

Once, I was helping a neighbor with his gas stove. He had unknowingly installed a valve meant for a water system. It was a costly mistake that could have been avoided by a simple check of the specifications. Have you ever been in a situation where you realized too late that you had the wrong tool for the job? Ensuring you have the correct valve type can save you from unnecessary headaches and potential danger.

In both cases of improper fitting and incorrect valve type, the takeaway is clear: attention to detail during installation is paramount. Always ensure the right tools and parts are used and double-check every connection. Your safety and peace of mind are worth it.

Maintenance Neglect

Gas valve failure often stems from neglecting regular maintenance. Dust, debris, and corrosion can damage valves over time. Routine checks and cleaning help prevent these common issues.

Maintenance neglect is a common culprit when it comes to gas valve failure. Ignoring the upkeep of these critical components can lead to severe consequences. It might seem like a hassle, but regular attention to maintenance can save you from costly repairs or dangerous situations.

Lack Of Regular Inspections

Skipping regular inspections of your gas valves is like ignoring the check engine light on your car. You might get away with it for a while, but sooner or later, trouble will catch up. Regular inspections help identify potential issues before they turn into significant problems.

Have you ever thought about how a small leak, left unchecked, could escalate into a major gas leak? A simple inspection could prevent this scenario. Make it a habit to schedule a professional inspection at least once a year. This proactive step could be the difference between safety and disaster.

Failure To Replace Worn Parts

Over time, parts of your gas valve can wear out and need replacement. It’s tempting to ignore worn parts until they cause a noticeable issue. However, this can be a risky approach. Worn parts can lead to inefficient gas flow or even a complete shutdown of your system. Consider the washer in your kitchen faucet. When it wears out, the faucet starts leaking, right? Similarly, a worn-out component in your gas valve can lead to leaks. Ensure you have a routine check for worn parts.

Replacing them promptly can extend the life of your gas valve and prevent unexpected failures. Are you taking the necessary steps to maintain your gas valves, or are you leaving it to chance? Regular care and attention can safeguard your home and provide peace of mind.

Impact Of Wear And Tear

Gas valve failure can result from various factors. One significant cause is wear and tear. Over time, gas valves endure constant use. This leads to deterioration. Understanding the impact of wear and tear is crucial. It helps in maintaining the efficiency and safety of gas systems.

Aging Components

As gas valves age, their components wear down. Materials like rubber and plastic degrade. Metal parts may corrode or rust. This affects the valve’s performance. Older valves can become unreliable. They might not open or close properly. Regular inspections can identify aging components early. This prevents potential failures.

Mechanical Stress

Gas valves face mechanical stress. Frequent operation puts pressure on their parts. Stress can cause damage over time. Moving parts may wear out quickly. This leads to breakdowns. Mechanical stress affects valve seals. Leaky valves can result from damaged seals. Proper maintenance reduces stress effects. It ensures the valve’s longevity.

Credit: www.ebay.com

Manufacturing Defects

Gas valve failure often stems from manufacturing defects, impacting their performance. Materials and assembly errors can lead to leaks or malfunctions. Regular inspections and quality control during production help minimize these risks.

Manufacturing defects can be a silent culprit when it comes to gas valve failures. Picture this: you’ve just installed a new gas valve, expecting it to perform seamlessly, only to find it’s not working as it should. This can be both frustrating and potentially hazardous. Understanding the root causes behind these defects can empower you to make informed decisions and ask the right questions when purchasing or installing gas valves.

Defective Parts

Defective parts are often at the heart of manufacturing defects. Imagine buying a brand-new car, only to discover the engine is faulty. The same concept applies to gas valves—parts that aren’t manufactured correctly can lead to malfunctions. For example, a valve may have a poorly molded component that doesn’t fit properly, causing leaks or failure to control gas flow effectively.

Have you ever wondered why some products fail right out of the box? Often, it’s due to these defective parts slipping through the cracks during production. When purchasing gas valves, consider asking about the manufacturing process and the quality of the materials used.

Quality Control Issues

Quality control is the safety net that ensures defective parts don’t reach the end user. Without rigorous quality checks, flawed valves can easily make their way into your home or business. You might recall a time when you received a product that just didn’t meet your expectations; it’s likely quality control was lacking. Quality control issues can stem from inadequate testing procedures or oversight during production.

Think about the last time you were disappointed with a purchase—did you wish you had asked more questions about its quality? When buying gas valves, inquire about the manufacturer’s quality assurance protocols. This can help you avoid the inconvenience and risk of dealing with a faulty gas valve.

Preventive Measures

Gas valve failure can occur due to corrosion, dirt buildup, or manufacturing defects. Regular maintenance helps prevent these issues and ensures safety. Be alert to strange noises or leaks from the valve.

Gas valve failure can lead to significant issues, but taking preventive measures can greatly reduce the risk. By focusing on regular maintenance, proper installation, and quality assurance, you can enhance the longevity of your gas valves and ensure a safer environment. Let’s delve into these crucial aspects that can save you from potential hazards and costly repairs.

Regular Maintenance

Regular maintenance is your first line of defense against gas valve failure. Think of it like scheduling a health check-up for your valves. Inspect them routinely for signs of wear, corrosion, or leaks. Set reminders to check connections and seals. A visual inspection can reveal early signs of trouble, saving you from bigger issues down the line.

Make it a habit, just like checking the oil in your car. Involve professionals for thorough evaluations. A trained eye can spot issues you might miss. They can also guide you on specific maintenance tasks suitable for your valve type.

Proper Installation

Proper installation is crucial. A poorly installed gas valve is a ticking time bomb. Ensure that valves are fitted according to manufacturer guidelines. Use the right tools and techniques. Don’t rush the process; a quick installation can lead to mistakes.

Double-check connections and alignment to prevent leaks. Consider hiring certified professionals for installation. Their expertise can make a significant difference. It’s an investment in safety and efficiency.

Quality Assurance

Quality assurance is about choosing the right product from the start. Not all valves are created equal. Prioritize reputable brands known for durability and reliability. Research before buying. Check reviews and user feedback. You want a valve that has proven performance over time. Monitor valve performance after installation. If issues arise, address them promptly.

This proactive approach ensures the valve functions optimally throughout its lifespan. In summary, preventive measures are essential in avoiding gas valve failure. By dedicating time to maintenance, ensuring correct installation, and opting for quality products, you safeguard your home and peace of mind. What steps will you take today to ensure your gas valves are secure and reliable?

Credit: jayisontheway.com

Frequently Asked Questions

What Are Common Causes Of Gas Valve Failure?

Gas valve failure often happens due to wear, debris, or electrical issues. Regular maintenance can prevent these problems.

How Can I Detect A Faulty Gas Valve?

Signs of a faulty gas valve include irregular gas flow, strange noises, or persistent pilot light issues. Inspection helps.

Can A Gas Valve Failure Lead To Safety Risks?

Yes, a faulty gas valve can cause gas leaks, which are dangerous. Prompt repair is crucial for safety.

How Often Should Gas Valves Be Inspected?

Gas valves should be inspected annually to ensure proper functioning. Regular checks help identify potential issues early.

Final Words

Gas valve failure can disrupt daily life. It often results from wear, corrosion, or debris. Regular maintenance helps prevent these issues. Checking for leaks is important. Always use qualified professionals for repairs. Ignoring signs can lead to bigger problems. Safety should always come first.

Understanding the causes helps in preventing failures. Keep your gas systems in check. Proper care extends the life of your valves. Stay proactive, stay safe.