Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

To measure PVC pipe length between fittings, follow these steps: first, measure the distance between the fitting ends. Then, subtract the fitting depth from this measurement.

PVC pipes are common in plumbing systems, used for water supply and drainage. Knowing how to measure pipe length accurately is essential for a successful installation. This task can seem tricky due to the various types and sizes of fittings.

However, with the right approach, you can measure PVC pipe length between fittings with ease. This guide will help you understand the basic steps and techniques, ensuring your plumbing projects are precise and efficient. Whether you’re a DIY enthusiast or a professional, these tips will simplify your work and prevent common mistakes. Let’s dive into the process and make your next plumbing task a breeze.

Tools For Measuring Pvc Pipe

Measuring the length of PVC pipe between fittings can be a straightforward task if you have the right tools. Whether you’re a seasoned DIY enthusiast or just starting out, using the proper tools can make your project more accurate and efficient. Let’s look at some essential tools that can help you with this task.

Tape Measure

A tape measure is probably the most common tool you’ll find in any toolbox. It’s versatile and easy to use. When measuring PVC pipe, ensure your tape measure is long enough to cover the entire length of the pipe. Start by hooking the end of the tape measure onto one fitting and extend it to the next fitting. This will give you a clear measurement of the pipe length needed.

Remember that tape measures can bend, which might affect accuracy. Hold it steady and at eye level for a precise read. A personal tip: use a tape measure with a locking mechanism. It prevents the tape from retracting unexpectedly, allowing you to note down the measurements without hassle.

Calipers

Calipers are a bit more advanced but offer high precision. They are particularly useful for measuring smaller sections of PVC pipe or when you need exact diameter measurements. Using calipers can be intimidating at first, but once you get the hang of it, they’re incredibly accurate. Simply open the jaws, fit them around the pipe, and read the measurement on the scale.

If you’ve ever struggled with mismatched fittings, calipers can be a lifesaver. They ensure you have the right dimensions before cutting or fitting. It’s like having a reliable friend by your side who ensures everything fits perfectly.

Have you ever wondered why your fittings sometimes don’t align perfectly? It could be a measurement issue. Using the right tools not only saves you time but also ensures your plumbing projects are seamless. What tool do you prefer when tackling PVC pipes? Share your experiences or tips below!

Choosing The Right Pipe Size

Measuring PVC pipe length between fittings is simple with a few easy steps. Use a tape measure to find the distance between the ends of each fitting. Ensure accuracy to avoid leaks and ensure a proper fit in your plumbing projects.

Choosing the right pipe size is crucial when working with PVC pipes, especially when you’re trying to measure the length between fittings. Not only does the pipe size affect the flow of water or air, but it also impacts the overall efficiency of your project. Selecting the correct diameter and length can be the difference between a seamless installation and a frustrating one.

Diameter Considerations

The diameter of a PVC pipe isn’t just about the size of the hole in the middle. It affects how much fluid can pass through at any given time. Larger diameters allow for more flow, which might be necessary for high-demand areas like main water lines.

Think about the purpose of your pipe. Is it for a simple garden irrigation system or a more complex plumbing setup? Your needs will guide your diameter choice. Always check the pipe’s outer diameter, as this will determine how well it fits with your fittings.

Length Requirements

Determining the correct length of PVC pipe is essential for minimizing waste and ensuring proper fit. Measure the distance between fittings carefully, taking into account any bends or curves. It can be helpful to use a flexible measuring tape to get a more accurate reading.

Remember, it’s not just the straight path you need to consider. Think about how the pipe will navigate around corners or obstacles. Do you have spare pipe in case of errors? Having a little extra can save you a trip to the hardware store.

Have you ever found yourself standing in the plumbing aisle, overwhelmed by the choices? It’s a common scenario, but with a clear understanding of your project’s requirements, you’ll make confident decisions. Always bring your measurements with you and don’t hesitate to ask for advice. You might just learn a trick or two from the experts.

Understanding Fitting Types

Understanding the different fitting types is crucial when measuring PVC pipe length between fittings. Each fitting type serves a unique purpose and knowing these can save you both time and effort. Let’s dive into the specifics of some common fittings you might encounter.

Elbows And Tees

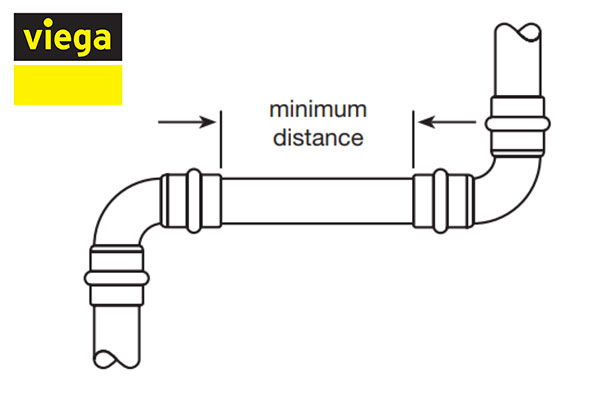

Elbows and tees are essential for changing the direction or branching off the pipeline. Elbows typically come in 90-degree and 45-degree angles. You might remember the time you were fixing a garden irrigation system; using a 90-degree elbow helped you navigate around a corner seamlessly.

Tees, on the other hand, allow you to split the flow into two directions. Imagine setting up a water supply for both your front and back yard. The tee fitting makes it easy to branch off and ensure water reaches both areas without additional hassle.

Couplings And Adapters

Couplings connect two pieces of PVC pipe together. They’re straightforward but essential, especially when extending the length of an existing pipeline. Think of them as the perfect solution when you underestimate the length of pipe needed for a backyard project.

Adapters are versatile fittings used to connect PVC pipes to pipes made of different materials. If you have an older metal pipe system and want to switch to PVC, adapters are your go-to option. They make the transition smooth and efficient, saving you from potential leaks and mismatches.

Have you ever wondered how these fittings impact the measurements of your PVC pipes? Correctly accounting for the length each fitting adds or reduces can ensure your project goes off without a hitch. What challenges have you faced while working with PVC fittings, and how did you overcome them?

Credit: www.youtube.com

Calculating Pipe Length

Understanding how to measure PVC pipe length between fittings is vital. It ensures a proper fit and prevents leaks. A precise calculation of pipe length is crucial for successful plumbing projects. Misjudging these measurements can lead to costly errors. This section will guide you through the essentials of calculating pipe length effectively.

Include Fitting Depth

Fitting depth is essential to consider in your calculations. Each fitting has a specific depth that affects the total pipe length. Check the manufacturer’s specifications for accurate measurements. Measure from the end of one fitting to the start of the next. Add the fitting depth to your total pipe length.

Account For Pipe Expansion

PVC pipes can expand with temperature changes. This expansion affects the overall length. Use expansion coefficients to estimate changes. Adjust your measurements accordingly to ensure accuracy. Consider environmental factors in your calculations. Proper allowances prevent stress and potential damage to the system.

Common Mistakes In Measurement

Measuring PVC pipe length between fittings often leads to errors. Incorrectly marking pipe ends or not accounting for fitting depth are common mistakes. Accurate measurements ensure a proper fit and prevent leaks.

Measuring PVC pipe length between fittings can seem straightforward, but common mistakes can lead to costly errors. Whether you’re working on a DIY plumbing project or a professional installation, precision is key. Missteps in measurement not only waste resources but can also lead to a less efficient system. So, what are these common pitfalls, and how can you avoid them?

###

Overlooking Fitting Size

One common mistake is overlooking the fitting size. Fittings add length to your piping system, and if not accounted for, can throw off your entire measurement.

Have you ever cut a pipe, only to realize it’s too short because you didn’t consider the fitting length? It’s frustrating, right?

To avoid this, always measure from the fitting shoulder, not the pipe end. This ensures your measurements account for the additional length fittings add.

###

Ignoring Pipe Tolerance

Ignoring pipe tolerance can also lead to miscalculation. PVC pipes come with a manufacturing tolerance, a small variance in size that can affect your measurement accuracy.

Have you noticed how sometimes the pipe doesn’t fit as snugly as expected? This could be due to ignoring these tolerances.

Check the manufacturer’s specifications for your PVC pipe. They often provide a tolerance range, which can guide you in making more precise cuts. Adjust your measurements based on this range to ensure a perfect fit.

Understanding these common mistakes can save you time and effort. By paying attention to fitting sizes and pipe tolerance, you can avoid unnecessary frustration and achieve a seamless installation. So, next time you measure PVC pipe, remember these tips and see if your project goes smoother. Have you encountered these mistakes before? How did you handle it?

Pro Tips For Accurate Measurement

Accurate measurement of PVC pipe length between fittings is crucial for seamless installation and avoiding costly errors. Whether you’re a seasoned DIYer or just starting out, getting precise measurements can save time and resources. Let’s dive into some pro tips that can help you achieve the perfect fit every time.

Double-check Measurements

Have you ever cut a pipe, only to find it’s a tad too short or long? It’s a common mishap, but preventable. Always double-check your measurements before cutting. Measure twice, cut once. This old adage holds true, especially when working with PVC pipes.

Consider using a piece of scrap material to test your measurements. It can act as a physical template, ensuring that your readings are spot-on before you make the final cut. A small investment in time can save a lot of frustration later.

Use Consistent Tools

Using different tools can lead to inconsistent measurements. Stick to the same measuring tape or ruler throughout your project. This consistency helps maintain accuracy, minimizing the risk of errors.

Also, ensure your tools are in good condition. A worn-out measuring tape can stretch, leading to inaccurate readings. Regularly check your tools and replace them if needed. Precision hinges on the reliability of your instruments.

Have you ever found yourself with mismatched pipe lengths despite careful measuring? It might be the tools. Consistent tools are your ally in achieving perfect symmetry in your project.

What’s your go-to strategy to ensure accurate measurements? Share your tips and tricks in the comments below. Engaging with fellow enthusiasts can uncover new insights and refine your approach.

Adjusting For Complex Configurations

Measuring PVC pipe length between fittings requires accuracy and attention. Start by measuring the pipe’s outer edge to the fitting’s center. This ensures precise fitting and avoids leaks. Always double-check measurements for complex configurations.

Adjusting for complex configurations in PVC pipe installations can seem daunting, especially when you’re trying to measure pipe length accurately between fittings. But with a clear understanding and a few tricks up your sleeve, you can manage even the most intricate setups with ease. Whether you’re dealing with multiple fittings or angled connections, the key is precision. Let’s dive into how you can handle these challenges effectively.

Handling Multiple Fittings

When you have numerous fittings in your piping system, it can feel like you’re piecing together a puzzle. Start by listing all the fittings you will use.

Measure each section between the fittings individually.

Use a tape measure for accuracy.

Ensure you leave enough space for the fittings themselves, as they add to the overall length.

If you’ve ever been frustrated by a pipe that was too short, you know the importance of this step.

Double-check your measurements and allow for a little extra length to accommodate any errors.

Working With Angled Connections

Angled connections require a bit more finesse. They can change the direction and length of your piping system.

Use a protractor to determine the exact angle of your connections.

This tool helps you calculate how much pipe length will be needed to maintain the desired flow.

Consider the angle’s impact on the water pressure and flow rate.

I once underestimated the angle’s effect, and it led to a reduced water flow in my garden irrigation system.

Ensure that each angle is accounted for and adjust your pipe length accordingly.

Are you ready to tackle these complex configurations? Remember, the key is understanding the fittings and angles, and measuring carefully. How do you plan to approach your next PVC pipe project?

Safety Precautions

When measuring PVC pipe length between fittings, safety should be a priority. Proper safety precautions protect you and ensure accurate measurements. Below are some essential safety tips to follow.

Protective Gear

Wear gloves to protect your hands from sharp edges. Safety glasses shield your eyes from flying debris. Using ear protection can help in noisy environments. A dust mask is useful if cutting the pipe creates dust.

Safe Handling Techniques

Use both hands when carrying PVC pipes. This prevents dropping and injury. Keep your workspace clean to avoid tripping hazards. Secure the pipe in place before measuring or cutting. Use a steady, firm grip when cutting to avoid accidents.

Credit: www.cooneybrothers.com

Frequently Asked Questions

How Do You Measure The Length Of A Pipe Between Fittings?

Measure the pipe length from the center of one fitting to the center of the adjacent fitting. Use a tape measure for accuracy. Ensure both fittings are securely attached before measuring. This method ensures precise measurements for installation or replacement tasks.

How Do You Measure Pvc Pipes Correctly To Prevent Fitting Mistakes?

Measure PVC pipes by their internal diameter. Use a caliper for precise measurements. Check the pipe’s labeling for size. Cut pipes cleanly and squarely. Dry fit all pieces before final assembly.

How Far Does Pvc Pipe Go Into Fitting?

PVC pipe typically goes into a fitting by about 1. 5 inches for a 1-inch pipe. The insertion depth varies by pipe size. Always check the manufacturer’s guidelines for precise measurements.

How To Measure Pvc Pipe For Coupling?

To measure PVC pipe for coupling, use a tape measure to find the outer diameter accurately. Ensure precision for a proper fit. Check the manufacturer’s specifications for compatibility. Clean the pipe ends before measuring to avoid errors. Always double-check measurements for the best results.

Final Words

Measuring PVC pipe length between fittings can seem daunting. But it’s simple. Start with the right tools. A tape measure is essential. Measure accurately to avoid errors. Remember to consider fitting depths. Fittings can impact length calculations. Double-check measurements for accuracy.

Precision is key to a successful project. Practice makes perfect. Keep your measurements consistent. This ensures a smooth installation process. Proper planning saves time and effort. With patience, you’ll gain confidence. Soon, measuring PVC pipe will be second nature. Enjoy the satisfaction of a job well done.

Happy measuring!