Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

PVC pipes are common in plumbing. But, how far do they go into fittings?

Knowing the correct insertion depth is vital. It ensures a secure and leak-free connection. This knowledge helps in both DIY projects and professional plumbing. We’ll explore the standard depths for PVC pipes in different fittings. Understanding this will make your plumbing tasks easier.

So, let’s dive in and get the details right. This way, your next project will be a success.

Pvc Pipe Basics

PVC pipes are essential in plumbing systems worldwide. Understanding their basics can help in various DIY projects or repairs. This section focuses on PVC pipe basics, including material composition and common uses.

Material Composition

PVC stands for polyvinyl chloride. It is a type of plastic known for its durability and resistance to corrosion. This makes it an ideal choice for pipes. The material is lightweight, making it easy to handle and install. PVC pipes are created through a process called extrusion. This process shapes the heated plastic into hollow tubes. The resulting pipes are sturdy yet flexible. They can withstand pressure and temperature changes.

Common Uses

PVC pipes serve multiple purposes in various industries. In residential plumbing, they are used for water supply lines. Their resistance to rust ensures clean water flow. They are popular in irrigation systems for gardens and farms. Their flexibility allows easy adaptation to different layouts.

In construction, they are used in drainage systems. This helps in efficiently channeling wastewater away. PVC pipes are also used in electrical conduit systems. They protect wires from external damage.

Credit: www.reddit.com

Fitting Types

When you’re working on a project involving PVC pipes, understanding the different types of fittings is crucial. Fittings determine how pipes connect and how well they function. Choosing the right type can prevent leaks and ensure a smooth flow of materials. Let’s dive into the specific fitting types and see how far PVC pipes go into each.

Slip Fittings

Slip fittings are the most common type used in PVC piping systems. They offer a straightforward connection by allowing the pipe to slide directly into the fitting. This type of fitting typically allows the pipe to go in about 1.5 inches deep. This depth ensures a secure fit while leaving room for the adhesive to bond properly.

Imagine working on a weekend DIY project. You want a seamless look for your irrigation system. Slip fittings provide that clean finish without visible threads. Have you ever wondered if your glue job was strong enough? With slip fittings, the depth and adhesive combination make it reliable.

Threaded Fittings

Threaded fittings provide an alternative method of connecting PVC pipes. These fittings have internal threads that match the external threads on the pipe ends. Here, the pipe typically screws into the fitting about ¾ of an inch. This connection type is often used when a removable or adjustable joint is needed.

Consider the times you’ve needed to make adjustments to plumbing without cutting pipes. Threaded fittings offer flexibility. Ever found yourself tightening a fitting just a bit more to stop a drip? That’s the convenience threaded connections bring. They are perfect for areas that might need future modifications.

Understanding these fitting types helps in selecting the right one for your project. Which fitting type aligns with your needs? Whether it’s the seamless look of slip fittings or the adjustability of threaded ones, each has its place in the world of PVC piping. Make your choice wisely and enjoy leak-free plumbing.

Insertion Depth

Understanding the insertion depth of PVC pipes into fittings is crucial. It ensures a secure and leak-proof connection. This part of the process might seem simple. Yet, it requires precision and accuracy.

Standard Depths

Standard depths vary based on the pipe size. Most PVC pipes have a standard insertion depth. For example, a 1/2-inch pipe usually goes 3/4 inches into the fitting. A 3/4-inch pipe typically goes 7/8 inches in. These measurements are common industry standards.

Factors Affecting Depth

Several factors can affect the insertion depth of PVC pipes. Temperature changes can cause the pipe to expand or contract. This may alter the depth slightly. The type of fitting also plays a role. Some fittings have deeper sockets than others. The glue used can impact depth as well. Too much glue might prevent the pipe from seating fully.

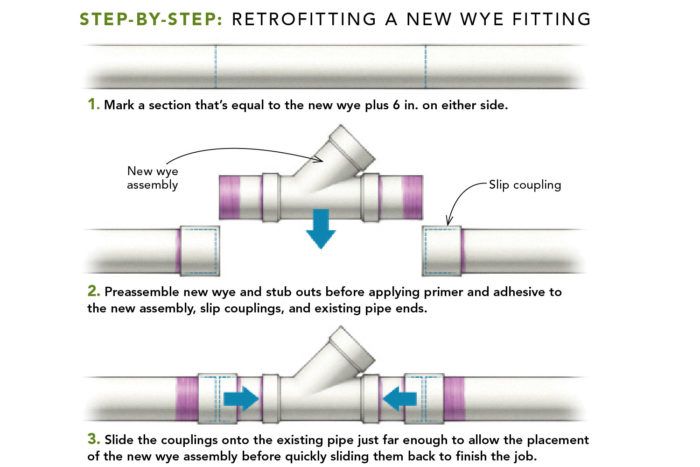

Credit: www.finehomebuilding.com

Measuring Techniques

Measuring the depth a PVC pipe goes into a fitting is crucial. It ensures a secure and leak-proof connection. Proper measurement helps in achieving the desired fit. There are various techniques to measure this accurately. Below, we explore two effective methods.

Using Tools

Tools offer precision in measuring pipe depth. A measuring tape or ruler is common. First, insert the pipe into the fitting fully. Then, mark the point where the pipe meets the fitting. Remove the pipe and measure the marked section. This gives the insertion depth. Calipers can also be used for more precision. They provide an exact depth measurement. Tools ensure consistency and accuracy every time.

Visual Inspection

Visual inspection is a simple method. It requires no tools. Insert the pipe into the fitting. Observe the point where it stops. The visible section gives a rough idea of depth. Compare the pipe’s length outside the fitting. This method is less precise but quick. It works well for small projects. Always ensure the pipe is fully seated in the fitting.

Installation Tips

Proper installation of PVC pipes ensures a strong and lasting connection. Understanding how far a PVC pipe goes into a fitting is key. Follow these installation tips for a successful setup.

Preparing The Pipe

Start by cutting the PVC pipe to the needed length. Ensure the cut is clean and straight. Use a fine-toothed saw or a specialized PVC cutter. Rough edges can cause leaks.

Next, deburr the edges of the pipe. A utility knife or sandpaper works well for this. Smooth edges help the pipe fit snugly into the fitting.

Clean the pipe’s surface with a cloth. Remove any dust or debris. A clean surface ensures a better bond with the fitting.

Ensuring A Secure Fit

Apply primer to the outside of the pipe end. Also, apply it inside the fitting. Primer softens the PVC, allowing better adhesion.

Next, apply PVC cement to both the pipe end and the fitting. Work quickly, as the cement dries fast. Ensure an even coat for a strong seal.

Push the pipe into the fitting firmly. Twist it slightly as you push for a better fit. Hold it in place for a few seconds. This ensures the cement sets properly.

Allow the joint to cure fully. Follow the manufacturer’s instructions for curing time. A well-cured joint ensures a leak-free connection.

Common Mistakes

Installing PVC pipes can be tricky. Many make common mistakes during fitting. These errors can lead to leaks or poor connections. Understanding these mistakes is crucial for a successful installation.

Incorrect Depth

Push the PVC pipe into the fitting. Make sure it’s deep enough. Many installers don’t push it far enough. This can cause a weak connection. Measure the depth needed for the fitting. Mark the pipe to ensure proper depth. This step prevents gaps and leaks.

Improper Fitting

Choose the right fitting for your PVC pipe. Using the wrong size is a common error. Ensure the fitting matches the pipe’s diameter. A mismatch leads to loose connections. This can cause water to escape. Always double-check fittings before installation. Proper fitting ensures a secure and leak-free joint.

Troubleshooting Issues

When working with PVC pipes, ensuring a snug and secure fit is crucial. Sometimes, despite your best efforts, you might face issues like leaks, gaps, or even damaged pipes. Addressing these problems can be tricky, but a little troubleshooting can save you time and frustration. Let’s dive into some common issues and their solutions.

Leaks And Gaps

Leaks in PVC fittings are a common headache. They often occur when the pipe isn’t pushed far enough into the fitting or if there’s a gap due to uneven cuts. Ensure your pipe is cut straight and pushed in until it touches the fitting’s stop point. If leaks persist, consider applying PVC cement evenly around the pipe and fitting junction.

Have you ever noticed a tiny gap that won’t seal? It might be due to debris or dirt stuck in the fitting. Clean both the pipe and fitting thoroughly before assembly. If the issue remains, check for cracks in the fitting itself, which can cause small gaps.

Pipe Damage

Sometimes, the problem isn’t with the fitting but the pipe itself. A damaged pipe can disrupt the connection, causing leaks. Inspect your pipe for cracks or bends. Even minor damage can compromise the fitting’s integrity.

Think about the environment where the pipes are installed. Exposure to excessive sunlight can weaken PVC pipes, leading to damage. Consider using protective sleeves or installing pipes in shaded areas to prevent deterioration.

Are you facing repeated issues with damaged pipes? It might be time to reconsider your handling methods. Dropping or mishandling pipes can lead to unseen damage. Always store pipes properly and handle them with care during installation.

Troubleshooting PVC pipe issues can be straightforward with the right approach. Have you encountered similar challenges? Share your experiences and solutions in the comments below!

Maintenance And Care

Proper maintenance and care ensure PVC pipes and fittings last long. Regular checks and addressing wear and tear keep your plumbing system efficient. Knowing how far PVC pipe goes into a fitting matters. This knowledge aids in maintaining the integrity of your system.

Routine Checks

Perform routine checks on your PVC pipes for signs of damage. Look for cracks, leaks, or discoloration. These issues can indicate a need for repair or replacement. Ensure that pipes are securely fitted into the fittings. Loose fittings can lead to leaks and water damage.

Inspect joints and connections for any signs of weakness. This helps maintain the system’s efficiency. Use a flashlight to spot hidden issues in dark areas. Regular checks prevent major plumbing problems.

Addressing Wear And Tear

Addressing wear and tear on PVC pipes is crucial. Replace damaged pipes or fittings promptly to avoid leaks. Consider environmental factors that may affect pipe integrity. Sunlight and extreme temperatures can weaken PVC over time.

Use protective coverings for exposed pipes to extend their lifespan. Regularly clean the pipes to prevent blockages and buildup. This ensures smooth water flow and system efficiency.

Credit: formufit.com

Frequently Asked Questions

How Much Pipe Goes Into A Fitting?

The pipe insertion depth varies by fitting type and size. Check the manufacturer’s specifications for accurate measurements. Typically, pipes insert 1/2 to 1 inch into fittings. Always ensure a secure fit by measuring before installation. Proper alignment and secure insertion prevent leaks and ensure system efficiency.

Do Pvc Fittings Need To Be Fully Seated?

Yes, PVC fittings need to be fully seated to ensure a secure and leak-free connection. This prevents potential issues.

How To Measure Pvc Pipe Length Between Fittings?

To measure PVC pipe length between fittings, measure the distance between the fitting ends. Subtract the insertion depth of each fitting. Use a tape measure for accuracy. Ensure fittings are properly aligned for precise measurements.

How Far Does A Pipe Thread Into A Fitting?

A pipe generally threads into a fitting about three to four full turns. Ensure proper engagement for a secure connection. Use thread sealant for a better seal and prevent leaks. Always check manufacturer specifications for exact threading depth.

Final Words

Understanding how far PVC pipe goes into fittings is crucial. It ensures a secure connection. Proper measurement prevents leaks and maintains system efficiency. Always check the fitting depth before installation. This small step saves time and money. Remember to use the correct tools.

A misfit can lead to costly repairs. Practice makes perfect. Familiarize yourself with different fitting types. Each may have unique requirements. Knowledge is power in plumbing. With these tips, your PVC projects will succeed. Keep learning and improving your skills.

Your efforts will pay off in the long run.