Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

Choosing the right material for your underground piping system can feel overwhelming. With so many options available, how do you decide between HDPE and PVC pipes?

Each has its own strengths and weaknesses, and making the wrong choice could cost you time and money. You’re not alone in this dilemma, and understanding the differences is crucial. Imagine having peace of mind knowing you’ve chosen the best material for your project.

We’ll break down the pros and cons of HDPE and PVC pipes for underground use. By the end, you’ll have a clear understanding of which option aligns best with your needs, ensuring a durable and efficient solution. Stick with us as we guide you through this important decision-making process.

Material Composition

Choosing between HDPE and PVC pipes for underground use requires understanding their material composition. Each type has unique properties that affect performance and durability.

Hdpe Characteristics

HDPE stands for High-Density Polyethylene. It is a thermoplastic polymer. Its composition includes ethylene molecules. These molecules bond to form long chains. HDPE is flexible and resistant to impact. It withstands harsh environmental conditions. This makes it ideal for underground installations.

HDPE pipes are known for their durability. They resist corrosion and chemical reactions. This ensures long-lasting performance. The material is lightweight, simplifying transportation and installation. It also offers excellent flow capacity. This reduces energy costs during fluid transport.

Pvc Characteristics

PVC stands for Polyvinyl Chloride. It is a synthetic plastic polymer. PVC composition includes chlorine and carbon atoms. These form a strong, rigid structure. PVC pipes are less flexible than HDPE. They offer high tensile strength. This makes them suitable for certain underground applications.

PVC pipes resist corrosion and abrasion. They are easy to install due to their lightweight nature. PVC is cost-effective, appealing for budget-conscious projects. It offers good chemical resistance. This makes it suitable for transporting various fluids. Though less flexible, it maintains structural integrity under pressure.

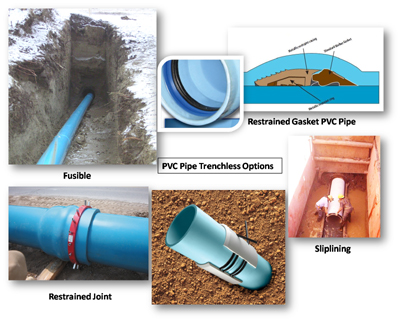

Credit: trenchlesstechnology.com

Durability And Longevity

Choosing the right pipe for underground use is crucial. Durability and longevity are key factors to consider. HDPE and PVC pipes offer unique benefits. Let’s explore their differences.

Resistance To Corrosion

HDPE pipes resist corrosion effectively. They do not rust or rot. This makes them ideal for underground installations. PVC pipes also resist corrosion well. But they can degrade under certain conditions. HDPE’s resistance ensures longer-lasting performance.

Impact Resistance

HDPE pipes are highly impact-resistant. They can withstand external pressures without damage. This makes them suitable for rugged environments. PVC pipes are less impact-resistant. They are more prone to cracking under stress. HDPE provides better protection in challenging conditions.

Installation Considerations

Choosing the right pipe for underground installations is crucial. Both HDPE and PVC pipes have unique attributes. Understanding installation considerations can help you make the best decision. Let’s explore key factors like flexibility, ease of installation, and jointing techniques.

Flexibility And Ease Of Installation

HDPE pipes offer high flexibility. They can bend without breaking, making them ideal for uneven terrain. This flexibility reduces the need for fittings in certain applications. PVC pipes are less flexible. They require more fittings for bends and turns. This can increase installation time and cost.

Jointing Techniques

HDPE pipes often use heat fusion for joints. This method creates a strong and seamless connection. It prevents leaks and enhances durability. PVC pipes usually rely on solvent cement or rubber gasket joints.

These methods can be quicker but may not offer the same strength. Each jointing technique has its pros and cons. Consider the project’s specific needs for the best choice.

Credit: creekplastics.com

Cost Comparison

Choosing the right pipe for underground use involves understanding costs. HDPE and PVC pipes both offer unique advantages. Here, we compare their expenses to help you make an informed decision.

Material Costs

HDPE pipes often have higher material costs than PVC. This difference depends on the size and type of pipe. HDPE is more durable, which can justify the price. PVC is usually cheaper but may not last as long. Consider your budget and long-term needs when choosing.

Installation And Maintenance Costs

Installation costs for HDPE pipes may be higher. They require specialized equipment and skilled labor. PVC pipes are easier to install. Fewer tools and less skill are needed, reducing costs. Maintenance varies between the two. HDPE pipes are less prone to leaks, reducing repair costs over time. PVC may need more frequent repairs.

Environmental Impact

Choosing between HDPE and PVC pipes for underground use affects the environment differently. HDPE is recyclable, reducing landfill waste. PVC requires more energy in production, impacting carbon footprint.

When choosing materials for underground piping, the environmental impact is a significant consideration. HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) are popular options, each with unique environmental footprints. Which is more eco-friendly? Let’s explore key factors like recyclability and manufacturing processes to find out.

Recyclability

HDPE pipes are highly recyclable. They can be melted down and reformed without losing quality. This ability to be reused makes HDPE a sustainable choice for those conscious about the environment. PVC pipes, on the other hand, are less recyclable.

The recycling process for PVC is more complex due to the additives used in its production. This complexity often discourages recycling, leading to more waste. You might wonder, does this mean HDPE is always the better choice? Not necessarily. Consider the overall lifecycle and the specific needs of your project.

Manufacturing Processes

The manufacturing process of HDPE is energy-efficient. It involves fewer emissions, contributing to a smaller carbon footprint. This efficiency makes HDPE attractive for eco-conscious projects. PVC manufacturing requires more energy and releases harmful chemicals. These emissions can impact air quality and contribute to environmental degradation.

However, advancements in technology are making strides in reducing these impacts. Think about the broader implications. Does the energy used in production outweigh the benefits of durability and cost? Balancing these factors is crucial when deciding between HDPE and PVC. Choosing the right pipe for your underground project involves more than just cost and durability.

Environmental impact is a vital aspect that could affect your decision. By understanding recyclability and manufacturing processes, you can make a more informed choice that aligns with your environmental values. How will you weigh these factors in your next project?

Performance In Various Soil Conditions

Choosing the right underground pipe depends on soil conditions. HDPE and PVC pipes perform differently in various soils. Understanding their performance helps in making informed decisions.

Soil Movement Adaptability

HDPE pipes adapt well to soil movement. They are flexible and can bend without breaking. This flexibility makes them ideal for areas with shifting soils. PVC pipes, in contrast, are rigid. They can crack under pressure from moving soil. In stable soil, PVC can work effectively. But in areas prone to shifts, HDPE is the safer choice.

Chemical Resistance

Both HDPE and PVC pipes resist chemicals. HDPE offers better resistance to acids and alkalis. This makes it suitable for harsh chemical environments. PVC also resists many chemicals but has limitations.

It may not perform well with certain solvents. Choosing between them depends on soil’s chemical properties. HDPE is preferred in chemically aggressive soils.

Common Applications

HDPE and PVC pipes are popular for underground applications due to their durability and cost-effectiveness. HDPE offers flexibility and resistance to chemicals, ideal for uneven terrains. PVC, on the other hand, provides strong, rigid support for constant pressure systems. Both materials ensure efficient water and gas transportation underground.

When considering materials for underground piping, both HDPE and PVC pipes are popular choices due to their durability and versatility. Each has unique applications that make it suitable for different scenarios. Understanding where each type of pipe excels can help you make an informed decision based on your specific needs.

Residential Uses

In residential settings, HDPE and PVC pipes are often used for water supply and drainage systems. HDPE pipes are flexible, making them ideal for areas prone to ground movement. This flexibility can prevent breaks and leaks, offering peace of mind in earthquake-prone regions.

PVC pipes, on the other hand, are commonly used for sewer lines and irrigation systems due to their rigidity and ease of installation. Imagine installing a new garden irrigation system; the lightweight nature of PVC can make your job much simpler and quicker. Have you ever considered how the type of piping impacts the longevity of your home systems?

Commercial And Industrial Uses

In commercial and industrial applications, HDPE pipes are favored for their high resistance to chemicals and corrosion. They are frequently used in industrial process water systems and for transporting hazardous materials safely. Their durability can be a game-changer in environments where reliability is critical.

PVC pipes are often chosen for ventilation systems and non-pressure applications in commercial buildings. Their cost-effectiveness makes them a go-to option for large-scale projects. Picture a sprawling commercial complex; using PVC can offer significant savings while ensuring efficient waste management.

Choosing between HDPE and PVC for your underground piping needs depends largely on the specific requirements of your project. Have you weighed the benefits of flexibility against the need for rigidity in your application?

Regulatory Standards

Understanding the regulatory standards for underground piping is crucial. It ensures safety and reliability. HDPE and PVC pipes must meet specific regulations. These standards guide their use in various applications. They help maintain performance and durability in underground settings.

Compliance Requirements

Both HDPE and PVC pipes have strict compliance requirements. These ensure safe and effective underground installations. HDPE pipes are known for their flexibility and durability.

Compliance involves testing for pressure and environmental resistance. PVC pipes, with their rigid nature, face different tests. They need to pass standards for impact and chemical resistance.

Industry Guidelines

Industry guidelines provide best practices for using HDPE and PVC pipes. These guidelines help choose the right pipe for specific conditions. For HDPE pipes, guidelines often emphasize installation techniques.

Proper installation minimizes risks of leaks and ensures longevity. PVC guidelines focus on joint fittings and sealing methods. They ensure that the pipes function correctly underground.

Credit: www.pvcconduitmanufacturer.com

Frequently Asked Questions

What Is The Main Difference Between Hdpe And Pvc Pipes?

HDPE pipes are flexible. PVC pipes are rigid. HDPE is better for underground use.

Which Pipe Is More Durable For Underground Use?

HDPE pipes are more durable underground. They resist cracking and root damage better.

Are Hdpe Pipes More Expensive Than Pvc Pipes?

HDPE pipes usually cost more. But they last longer and need less maintenance.

Which Pipe Is Easier To Install Underground?

HDPE pipes are lighter and easier to install. They bend easily around obstacles.

Final Words

Choosing the right pipe for underground use matters. HDPE pipes offer flexibility and durability. They resist corrosion and are easy to install. PVC pipes provide strength and are cost-effective. They handle pressure well and are light to transport. Both options suit different needs.

Consider your project requirements carefully. Think about budget, soil conditions, and longevity. HDPE and PVC pipes serve specific purposes. Consult experts for advice if unsure. Make informed decisions for successful installations. Proper pipe selection ensures lasting performance underground. Choose wisely for peace of mind and project success.