Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

ABS and PVC can be glued together using a special transition cement. This cement is specifically designed for bonding dissimilar plastics.

ABS (Acrylonitrile Butadiene Styrene) and PVC (Polyvinyl Chloride) are common materials in plumbing and construction. Gluing them requires a specific type of transition cement to ensure a strong bond. This cement chemically fuses the plastics, creating a durable connection. Using the correct adhesive is crucial for the structural integrity of the project.

Always clean the surfaces before applying the cement to ensure proper adhesion. Following these steps ensures a reliable and lasting bond between ABS and PVC materials. Properly bonded joints are essential for preventing leaks and ensuring the longevity of your plumbing system.

Introduction To Abs And Pvc

ABS and PVC are common materials in plumbing and construction. Both have distinct properties. Understanding these properties helps in using them effectively.

What Is Abs?

ABS stands for Acrylonitrile Butadiene Styrene. It is a type of plastic.

- ABS is lightweight.

- It is strong and durable.

- Resists impact and is tough.

- It is used for pipes and fittings.

ABS pipes are usually black. They are used in both residential and commercial plumbing. They can handle cold temperatures well. They are also resistant to chemicals.

What Is Pvc?

PVC stands for Polyvinyl Chloride. It is another type of plastic.

- PVC is versatile and flexible.

- It is used for pipes and fittings.

- It is strong and durable.

- Resists corrosion and chemicals.

PVC pipes are usually white or gray. They are used in various plumbing applications. They are also used in electrical conduits and building materials.

| Property | ABS | PVC |

|---|---|---|

| Color | Black | White or Gray |

| Temperature Resistance | Good for cold | Good for moderate |

| Flexibility | Less flexible | More flexible |

| Usage | Plumbing | Plumbing, electrical, building |

Both ABS and PVC have their own benefits. Knowing these can help in deciding their usage.

Properties Of Abs And Pvc

ABS (Acrylonitrile Butadiene Styrene) and PVC (Polyvinyl Chloride) are two popular types of plastic. Both have unique properties that make them suitable for various applications. Understanding these properties helps determine if ABS and PVC can be glued together.

Physical Attributes

ABS is known for its toughness and impact resistance. It has a smooth, glossy surface. PVC, on the other hand, is more rigid and durable. It has a matte finish.

Here is a comparison table:

| Property | ABS | PVC |

|---|---|---|

| Surface | Smooth, Glossy | Matte |

| Toughness | High | Moderate |

| Rigidity | Moderate | High |

Chemical Resistance

ABS has good resistance to acids and alkalis. It can withstand various chemical exposures. PVC also exhibits excellent chemical resistance. It resists corrosion and degradation from chemicals.

Here are their chemical resistance properties:

- ABS: Resistant to acids, alkalis, and oils.

- PVC: Resistant to acids, alkalis, and salts.

Both materials perform well in harsh environments. They maintain their integrity under chemical exposure.

Gluing Basics

When working with ABS and PVC pipes, knowing the basics of gluing is important. These materials are commonly used in plumbing and other construction projects. Understanding the right techniques and products ensures a strong and lasting bond.

Adhesion Fundamentals

Adhesion is the process where two different surfaces stick together. For ABS and PVC, proper adhesion requires using the right adhesive. The surfaces must be clean and free from dust, oil, or any contaminants.

Surface preparation is key. Sanding the surfaces lightly can help the glue bond better. Applying a primer can also improve adhesion, especially for PVC pipes.

Types Of Glues Used

Several types of glues can be used to bond ABS and PVC. Each has its unique properties and benefits:

| Type of Glue | Properties | Best Used For |

|---|---|---|

| ABS Cement | Fast-setting, strong bond | ABS to ABS joints |

| PVC Cement | Water-resistant, durable | PVC to PVC joints |

| Transition Cement | Works on both ABS and PVC | Joining ABS to PVC |

When using transition cement, ensure the glue is compatible with both materials. Follow the manufacturer’s instructions for the best results.

Here’s a simple step-by-step guide:

- Clean the surfaces thoroughly.

- Lightly sand the areas to be glued.

- Apply primer if necessary.

- Apply the chosen glue evenly.

- Join the pieces and hold them together until the glue sets.

Proper curing time is crucial. Allow the bond to fully set before applying any stress to the joint.

Can Abs And Pvc Be Glued Together?

Many people ask if they can glue ABS and PVC together. These are two common types of plastic used in plumbing. They have different properties and uses.

The General Consensus

The general consensus is mixed. Some experts say it is possible to glue ABS and PVC. Others suggest it might not be reliable. The key lies in the type of adhesive used.

Special adhesives called transition cements can glue ABS and PVC. They are designed to work with both types of plastics. Using the right adhesive increases the chance of success.

Factors Affecting Adhesion

Several factors affect the adhesion of ABS and PVC. Understanding these can help achieve a better bond.

- Surface Preparation: Clean surfaces ensure better adhesion. Remove any dirt or grease.

- Type of Adhesive: Use a transition cement. These adhesives are made for ABS and PVC.

- Temperature: Glue works better at room temperature. Avoid gluing in extreme cold or heat.

Below is a table summarizing these factors:

| Factor | Importance |

|---|---|

| Surface Preparation | High |

| Type of Adhesive | Very High |

| Temperature | Moderate |

How To Glue Abs To Pvc

ABS and PVC are both popular plastics in the plumbing industry. Many people wonder if they can be glued together. The good news is, you can glue ABS to PVC. This guide will help you understand the process.

Preparation Steps

Before gluing ABS to PVC, you need to prepare the materials.

- Clean the surfaces: Use a cloth to clean both ABS and PVC pipes. Make sure they are free of dirt and grease.

- Sand the edges: Lightly sand the edges of both pipes. This helps the glue stick better.

- Wipe again: After sanding, wipe the pipes with a clean cloth. Remove any dust particles.

- Dry the pipes: Ensure both pipes are completely dry before applying glue.

Application Techniques

Once the pipes are prepared, it’s time to apply the glue.

- Use the right glue: Select a glue that works for both ABS and PVC. Many stores sell specialized glue for this purpose.

- Apply a thin layer: Spread a thin layer of glue on the ABS pipe. Make sure the glue covers the entire surface.

- Join the pipes: Quickly push the ABS and PVC pipes together. Hold them in place for a few seconds.

- Let it cure: Allow the glue to dry completely. Check the glue’s instructions for curing time.

| Step | Action |

|---|---|

| 1 | Clean the surfaces |

| 2 | Sand the edges |

| 3 | Wipe again |

| 4 | Dry the pipes |

| 5 | Apply a thin layer of glue |

| 6 | Join the pipes |

| 7 | Let it cure |

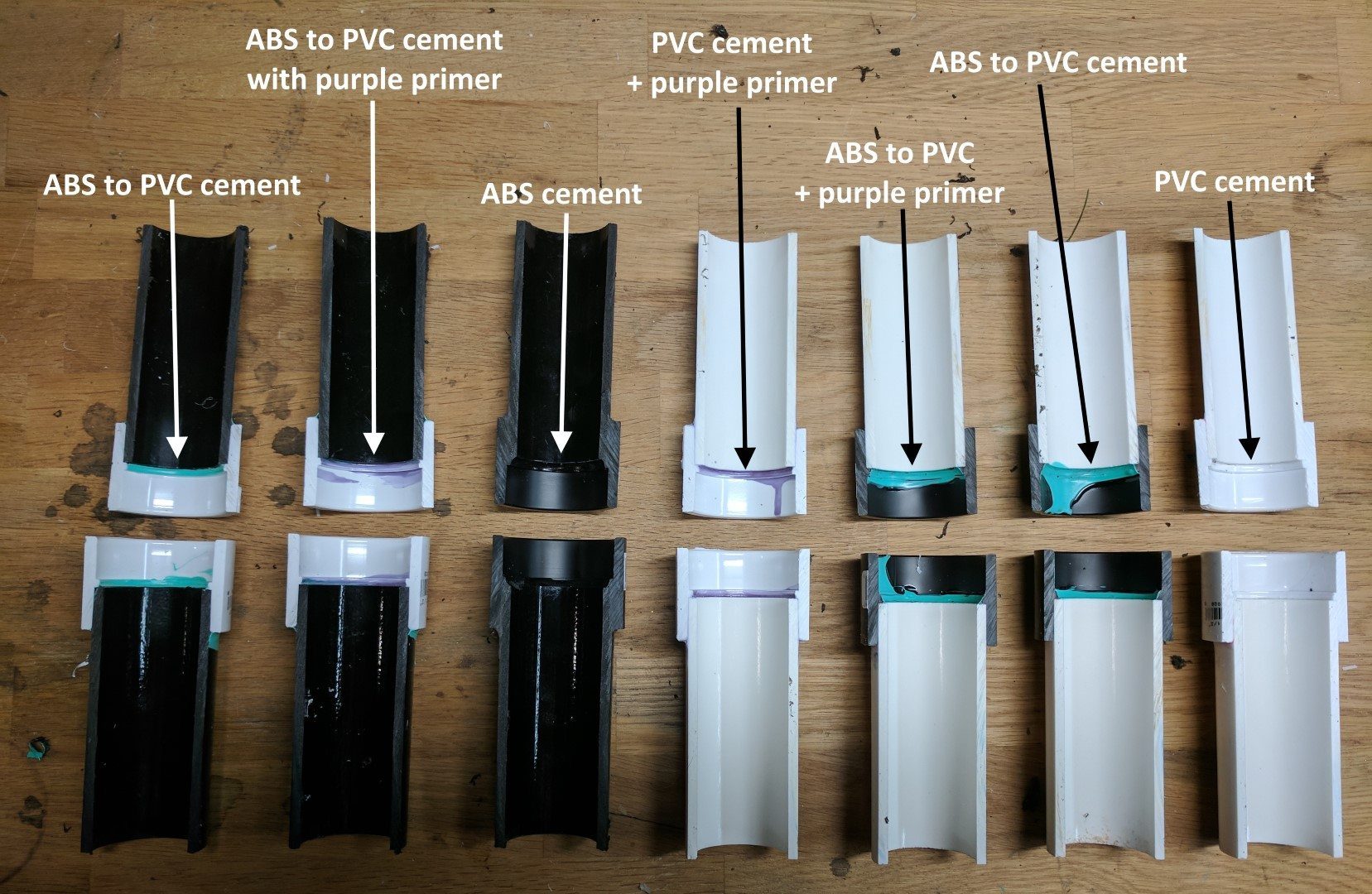

Credit: structuretech.com

Recommended Adhesives

Gluing ABS and PVC together can be tricky. The right adhesive is crucial for a strong bond. This section highlights the best options and what to avoid.

Best Glues For Abs And Pvc

Not all adhesives work well with ABS and PVC. Here are some top choices:

- ABS to PVC Transition Cement: This glue is specially made for bonding ABS and PVC.

- Two-Part Epoxy: This adhesive offers a strong bond and durability.

- Cyanoacrylate (Super Glue): Effective for small projects and quick fixes.

What To Avoid

Some adhesives are not suitable for ABS and PVC. Avoid these:

- Standard PVC Cement: It does not bond well with ABS.

- Hot Glue: It lacks the strength for durable bonds.

- Wood Glue: This glue is designed for wood, not plastics.

Challenges And Solutions

Gluing ABS and PVC together can be tricky. Each material has unique properties. This section explores the challenges and solutions.

Common Issues

Combining ABS and PVC poses several challenges. Both have different chemical compositions. This affects how they bond. Here are some common issues:

- Incompatible adhesives: Most glues work only with one type.

- Different melting points: ABS and PVC melt at different temperatures.

- Surface texture: Smooth surfaces can hinder bonding.

Troubleshooting Tips

To successfully glue ABS and PVC, follow these troubleshooting tips:

- Choose the right adhesive: Use a multi-purpose solvent cement.

- Clean the surfaces: Remove dirt and grease before gluing.

- Roughen the surfaces: Sand both surfaces to improve adhesion.

| Challenge | Solution |

|---|---|

| Incompatible adhesives | Use multi-purpose solvent cement |

| Different melting points | Apply heat evenly |

| Surface texture | Sand surfaces for better bonding |

Real-world Applications

Gluing ABS and PVC together can be useful for various real-world applications. From DIY projects to industrial uses, this combination is versatile and practical.

Diy Projects

Many hobbyists enjoy working with ABS and PVC in their home projects. These materials are easy to find and inexpensive. They can be used to create custom furniture, toys, or even home improvement solutions.

- Custom Furniture: ABS and PVC pipes can form the frame of tables or chairs.

- Toys: Create durable and safe toys for kids using these materials.

- Home Improvement: Use ABS and PVC for plumbing repairs or storage solutions.

These projects are simple and rewarding. You can find many guides and tutorials online to help you get started.

Industrial Uses

ABS and PVC are also popular in various industrial applications. They are known for their durability and resistance to chemicals.

| Industry | Use |

|---|---|

| Construction | Used in building structures and plumbing systems. |

| Automotive | Used in car interiors and exteriors. |

| Electronics | Used for housing and protective cases for devices. |

These industries rely on ABS and PVC for their specific needs. The materials offer strength and versatility for various applications.

Credit: www.reddit.com

Frequently Asked Questions

What Glue Works On Abs And Pvc?

For ABS and PVC, use solvent-based adhesives like PVC cement or ABS cement. These glues create strong, durable bonds.

Can Abs And Pvc Be Used Together?

ABS and PVC pipes can’t be directly glued together due to different chemical compositions. Use a mechanical coupling instead.

Why Can’t I Glue Abs To Pvc?

ABS and PVC have different chemical compositions. This difference prevents standard glues from effectively bonding them. Using a specialized adhesive designed for both materials is necessary.

Can You Use All Purpose Cement To Glue Abs To Pvc?

No, you should not use all-purpose cement to glue ABS to PVC. Use a transition cement specifically made for ABS and PVC.

Final Words

Gluing ABS and PVC together is possible with the right adhesive. Choose a solvent-based glue for the best results. Proper surface preparation is crucial for a strong bond. Always follow safety guidelines and manufacturer instructions. With these steps, you can ensure a durable and reliable connection between ABS and PVC materials.