Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

Are you confused about the differences between IPS and NPT? You’re not alone.

Navigating the world of pipes and fittings can be overwhelming, but understanding these two threading standards is crucial for ensuring the success of your plumbing or DIY projects. Whether you’re a seasoned professional or a weekend warrior, knowing when to use IPS (Iron Pipe Size) or NPT (National Pipe Tapered) can save you time, money, and a lot of frustration.

In this guide, we’ll break down the key distinctions, practical applications, and the hidden nuances of IPS and NPT, helping you make informed decisions with confidence. Stay with us to unravel the mystery and master the art of pipe threading.

Overview Of Ips And Npt

Understanding the differences between IPS and NPT is crucial in plumbing. Both terms refer to types of thread standards used in piping systems. Each has unique characteristics and applications. Knowing their basics helps in choosing the right one for your needs.

Basic Definitions

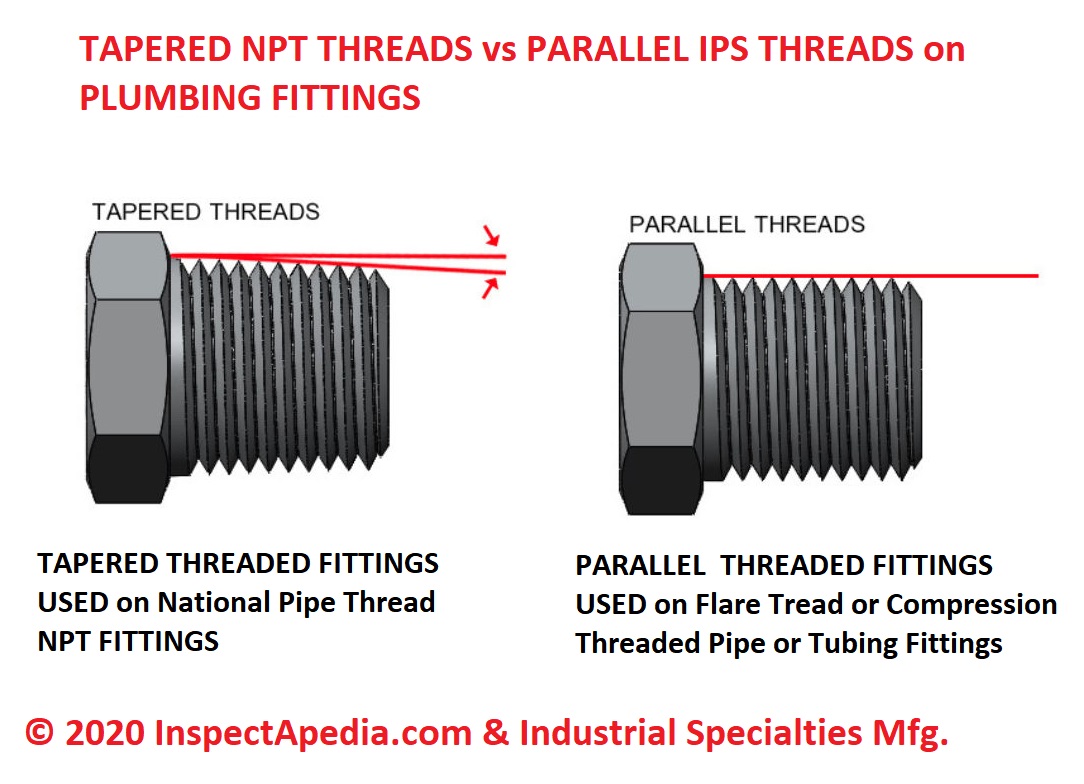

IPS stands for Iron Pipe Size. It is a standard for pipe thread sizes. This system is widely used in plumbing, especially in the United States. NPT stands for National Pipe Tapered threads. It is a standard for tapered threads used to seal pipes. These threads are designed to ensure a tight seal. Both IPS and NPT have specific uses in plumbing projects.

Historical Background

The IPS standard originated in the early 20th century. It was developed to create uniformity in pipe sizes. This standard helped streamline manufacturing processes. NPT threads were introduced around the same time. They provided a solution for sealing pipes effectively. Over the years, both standards have evolved. Today, they remain essential in plumbing and piping.

Credit: inspectapedia.com

Technical Specifications

Understanding technical specifications is crucial for selecting the right pipe threads. IPS (Iron Pipe Size) and NPT (National Pipe Thread) are two common types. Each has unique attributes and uses, impacting their performance in various applications. Let’s explore these technical details.

Design Standards

IPS threads follow specific design standards. They ensure compatibility with other piping systems. These standards define the thread dimensions and tolerances. NPT threads also adhere to strict design criteria. They are designed for a snug fit. This prevents leaks in pressurized systems.

Materials And Construction

IPS pipes are often made from iron or steel. They provide durability and strength. These materials withstand high pressure and temperature. NPT threads are typically used with brass or stainless steel. These materials resist corrosion. They are ideal for water and gas lines.

Application Areas

Exploring the application areas of IPS and NPT reveals their importance in piping systems. IPS, or Iron Pipe Size, is commonly used in industrial settings, ensuring strong connections. NPT, or National Pipe Thread, is favored for its tapered threads, providing a tight seal in plumbing.

Both play vital roles in ensuring efficient and secure fluid transportation.

When considering plumbing and piping systems, understanding the application areas of IPS (Iron Pipe Size) and NPT (National Pipe Thread) can save you time and avoid costly mistakes. Both standards serve different purposes and are used in various scenarios. Knowing where each excels can make a significant difference in your projects.

Common Uses Of Ips

IPS is primarily used for water distribution and fluid systems. It is particularly common in residential plumbing. If you have ever replaced a pipe under your sink or installed a new showerhead, you’ve likely encountered IPS. In the industrial sector, IPS is favored for transporting liquids and gases at lower pressures. It is a go-to choice for HVAC systems.

The reason is its ability to handle a moderate amount of pressure while maintaining durability. Even in agriculture, IPS pipes play a crucial role. They are often utilized in irrigation systems, ensuring water is efficiently directed to crops. This practical application can enhance crop yield and conserve water resources.

Common Uses Of Npt

NPT is a staple in high-pressure systems. If you are working with gas lines or hydraulic systems, NPT is your best bet. Its threaded design ensures a tight seal, which is essential for safety and performance. You will also find NPT in petrochemical industries. It is often used in oil refineries where high-pressure and high-temperature environments are standard.

This makes it ideal for applications requiring robust and secure connections. NPT is also prevalent in the manufacturing of machinery. The tight seal capability of NPT threads helps in maintaining the integrity of mechanical systems. It is a critical component in ensuring machinery operates smoothly and efficiently.

Have you ever wondered why some systems fail while others last for years without issues? The answer often lies in choosing the right type of piping connection. Understanding the application areas of IPS and NPT can be your first step toward a successful project.

Credit: www.buyfittingsonline.com

Installation And Maintenance

Choosing between IPS and NPT threads can impact installation and maintenance. IPS threads offer straightforward installation, while NPT threads ensure a tighter seal. Proper maintenance extends the lifespan of both systems.

Understanding the installation and maintenance of piping systems can save you from future headaches. Whether you’re dealing with Ips (Iron Pipe Size) or Npt (National Pipe Thread), knowing the right steps is crucial. This knowledge ensures your systems work efficiently and last longer.

Installation Processes

The installation process for Ips and Npt can differ slightly, but both require precision. Start by gathering all necessary tools, such as a wrench, pipe cutter, and tape measure. Make sure to have the right pipe sizes and fitting types for your project. While installing Ips, you may notice that it uses a standard measurement system. This means fittings and pipes of the same size will match perfectly.

This can make the installation quicker and more straightforward. On the other hand, Npt relies on tapered threads, which can be a bit trickier. As you tighten the fitting, the threads create a seal. Ensure you wrap the threads with Teflon tape to prevent leaks.

Have you ever thought about how important it is to check for leaks after installation? A small oversight can lead to significant issues later. Always test your system with water or air to ensure it’s sealed properly.

Maintenance Practices

Regular maintenance of your piping systems is key to keeping them in top shape. Start by conducting routine inspections for any signs of wear or damage. Look for rust, corrosion, or leaks that might need attention. Cleaning your pipes is another crucial step. Debris can build up over time, reducing efficiency. Use a pipe cleaner or a vinegar solution to keep them clear.

An often-overlooked practice is checking the pipe fittings regularly. Ensure they’re tight and secure. Loose fittings can lead to leaks, which can damage your property over time. Are you consistent with your maintenance schedule? Regular checks can prevent costly repairs and extend the lifespan of your system. Keep a record of all inspections and repairs to monitor the health of your system.

By focusing on proper installation and maintenance, you can ensure your Ips and Npt systems function smoothly. This proactive approach saves you time, money, and unnecessary stress in the long run.

Advantages And Disadvantages

Choosing between IPS and NPT threads involves understanding their benefits and drawbacks. IPS offers better sealing for water and gas systems, ensuring reliability. NPT, on the other hand, provides ease of installation due to its tapered design, though it may require sealing tape for effective performance.

When considering a piping system for your next project, understanding the advantages and disadvantages of various threading options is crucial. Two popular choices are IPS (Iron Pipe Size) and NPT (National Pipe Thread). Each has distinct features that can make or break your project depending on your specific needs.

Pros And Cons Of Ips

IPS, commonly used in commercial and industrial applications, offers a variety of benefits. One major advantage is its compatibility with a wide range of piping materials such as PVC, steel, and copper. This flexibility allows for easier integration into existing systems. However, the downside is that IPS requires precise installation. Any misalignment can lead to leaks or system failures.

Have you ever faced a situation where a small mistake cost you hours of rework? This is a common challenge with IPS. Another benefit is its robustness, making it ideal for high-pressure environments. Yet, the disadvantage lies in its weight. IPS pipes can be cumbersome, making them harder to handle during installation. Could this extra effort be justified by the system’s durability?

Pros And Cons Of Npt

NPT, known for its tapered threads, offers its own set of advantages. One key pro is its self-sealing nature. As you tighten the threads, they create a seal that minimizes the chance of leaks. This feature can save you time and headaches in the long run. However, one drawback is the potential for over-tightening. This can damage the threads, leading to costly repairs.

Have you considered the delicate balance required to ensure a proper seal without damaging the pipe? Another advantage of NPT is its widespread use in plumbing and gas lines, making it easy to source materials and find skilled labor. Yet, a significant con is its limited compatibility with some modern materials.

Are you prepared to deal with potential compatibility issues in your project? In your experience, have you found the perfect fit with either IPS or NPT? Understanding their pros and cons can help you make informed decisions and avoid common pitfalls.

Industry Standards And Compliance

Industry standards and compliance are crucial in the plumbing world. Two common threads are IPS and NPT. Both have unique specifications. Understanding these standards ensures safety and efficiency. Companies must adhere to strict guidelines. This prevents errors and ensures product quality. Let’s explore the regulatory requirements and certification processes for IPS and NPT.

Regulatory Requirements

Regulatory requirements define the rules for IPS and NPT. They ensure that fittings and threads meet specific criteria. Compliance is essential for safety and reliability. Governments set these standards to protect consumers. These regulations dictate thread dimensions and materials. Non-compliance can result in penalties or product recalls.

Manufacturers must stay updated on changes. This helps them maintain compliance. Regular audits often occur to check adherence. These audits ensure that products meet the necessary standards. Staying informed is vital for avoiding costly mistakes.

Certification Processes

Certification processes validate the quality of IPS and NPT products. They involve rigorous testing and inspection. Certification proves that products meet industry standards. It boosts consumer confidence in the product’s safety. Organizations conduct these certifications. They evaluate the product’s durability and performance.

Manufacturers submit products for testing. Experts check for compliance with established norms. Once certified, products gain a seal of approval. This seal signifies that the product meets all required standards. It assures buyers of the product’s reliability.

Maintaining certification requires constant vigilance. Companies must regularly review their processes. This ensures ongoing compliance and quality assurance. Certification is not a one-time event. It is an ongoing commitment to excellence.

Future Trends

The plumbing industry continuously evolves with new technologies and standards. IPS (Iron Pipe Size) and NPT (National Pipe Thread) are integral to this field. Understanding future trends in IPS and NPT can offer insights into the industry’s direction. These trends influence how plumbing systems are designed and implemented. Let’s explore the innovations shaping the future of IPS and NPT.

Innovations In Ips

IPS is witnessing advancements in material technology. New materials promise longer durability and better performance. These materials resist corrosion and withstand extreme temperatures. Another trend is the improvement in manufacturing processes. These processes aim to reduce costs while maintaining quality. Digital tools are also being integrated into IPS systems. They help in monitoring and managing plumbing networks effectively.

Manufacturers focus on sustainability. They develop eco-friendly IPS solutions to meet environmental standards. This includes using recyclable materials and minimizing waste. Such innovations ensure IPS remains relevant in modern plumbing systems.

Innovations In Npt

NPT is not left behind in the innovation race. Improved sealing technologies enhance the reliability of NPT connections. These technologies prevent leaks and ensure tight fittings. Automation in production processes is another trend. It ensures precision and consistency in NPT products.

Smart technology integration is also making waves. NPT systems now incorporate sensors and IoT devices. These tools provide real-time data for system maintenance and troubleshooting. Manufacturers are also exploring the use of advanced coatings. These coatings provide additional protection against wear and tear.

The future of NPT is promising with these innovations. They enhance the efficiency and reliability of plumbing systems.

Frequently Asked Questions

What Is The Difference Between Ips And Npt?

IPS stands for Iron Pipe Size, while NPT means National Pipe Tapered. They refer to different pipe threading standards.

Can Ips And Npt Threads Be Used Together?

No, they are incompatible. IPS and NPT threads have different angles and dimensions. Mixing them may cause leaks.

Why Are Npt Threads Commonly Used?

NPT threads are popular for their sealing capabilities. Their tapered design helps create tight seals in pipes.

How Do I Identify Ips Threads?

IPS threads are parallel and consistent in diameter. Measure the outside diameter to identify them correctly.

Final Words

Choosing between IPS and NPT can feel confusing. Both have unique uses and benefits. IPS works well for industrial applications. NPT is ideal for plumbing projects. Understanding your specific needs helps in making the right choice. Consider the pressure, environment, and material compatibility.

These factors guide your decision. Remember, the right fitting ensures safety and efficiency. Make informed choices for successful outcomes. Always consult professionals if in doubt. They provide valuable insights and expertise. Your project depends on the right fittings. Choose wisely and ensure long-lasting results.